ENBL: Efficient, Scalable, and Trusted Grab Manufacturing

10+ Years of Grab Manufacturing Experience

Founded in 2013 with a proven track record in professional grab manufacturing and global service.

Dual Manufacturing Bases

Kunshan (14,700 m²) + Ma'anshan (52,000 m²) for scalable output and faster lead times.

Strong Capital Support

Total registered capital: 87.4 million CNY, enabling sustainable growth and stable supply.

Custom Grab Solutions

Wide range of electro-hydraulic, mechanical, and specialty grabs tailored to specific industries.

Kunshan Headquarters Established

- Established & Location: 2013, Kunshan, Jiangsu

- Area: Workshop Area 14,700 m²,Covering 22 acres

- Registered Capital: 57.4 million CNY

Ma'anshan Factory Fully Operational

- Established & Location: 2023, Ma'anshan, Anhui

- Area: Workshop Area 52,000 m², Covering 78 acres

- Registered Capital: 30 million CNY

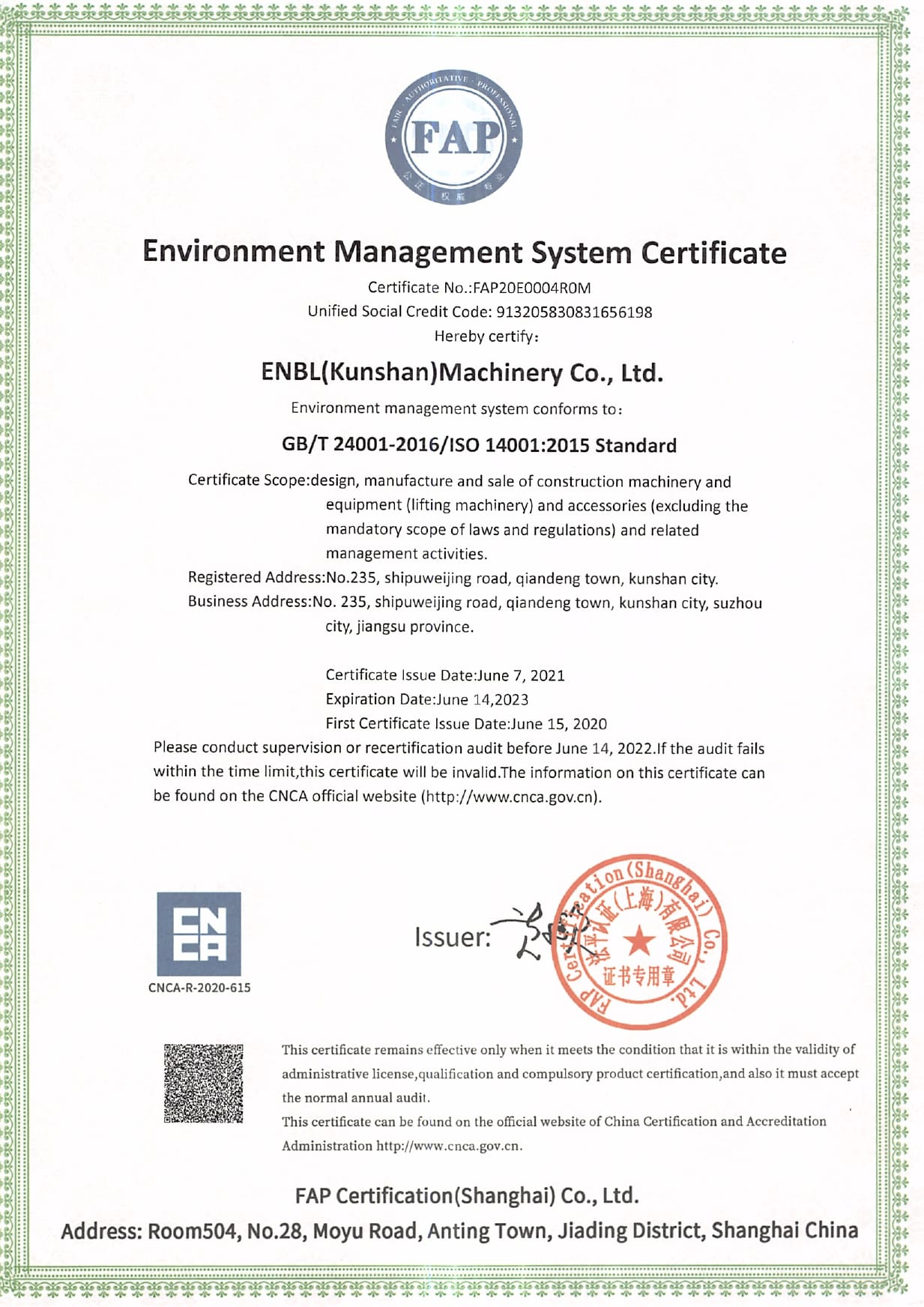

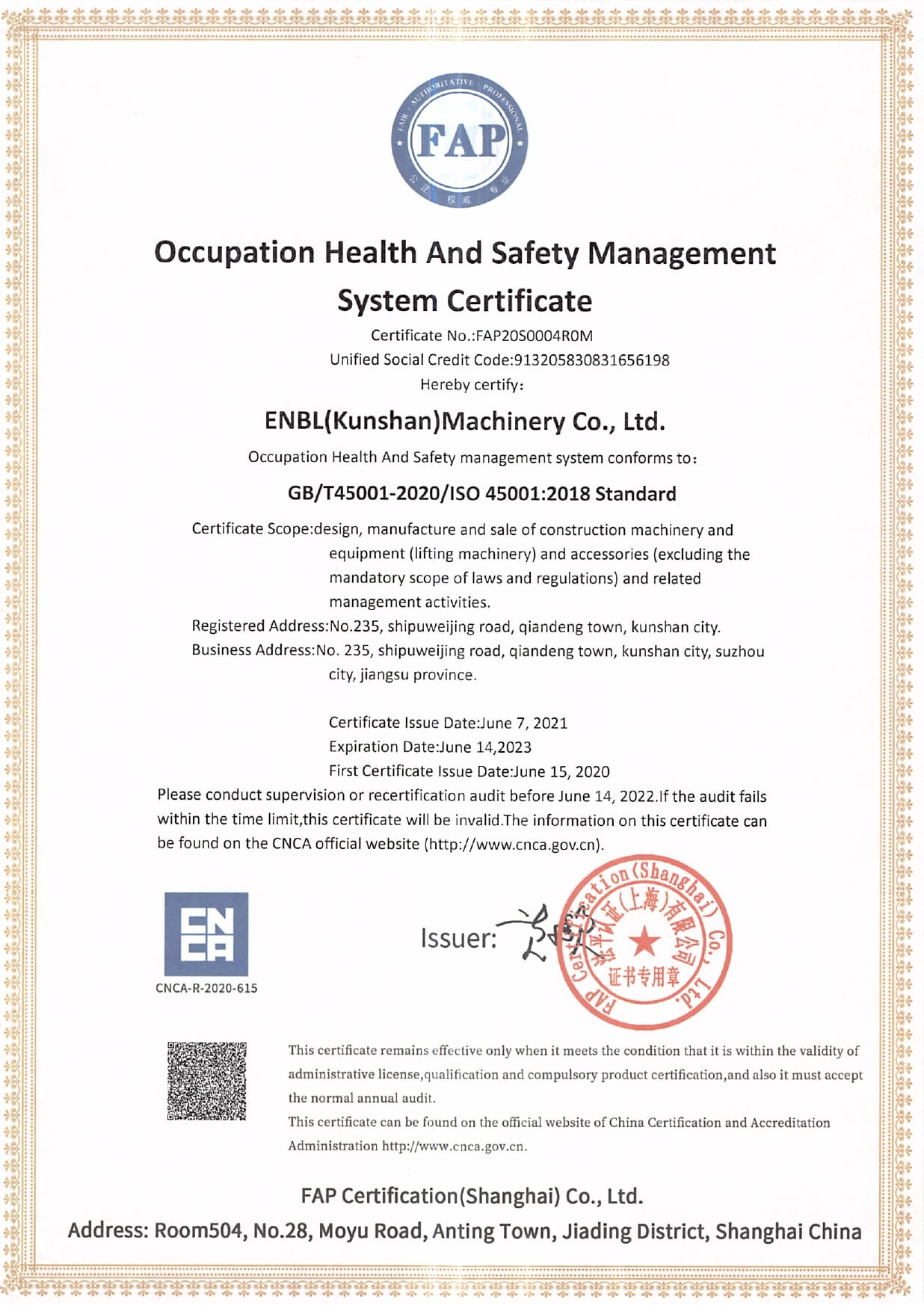

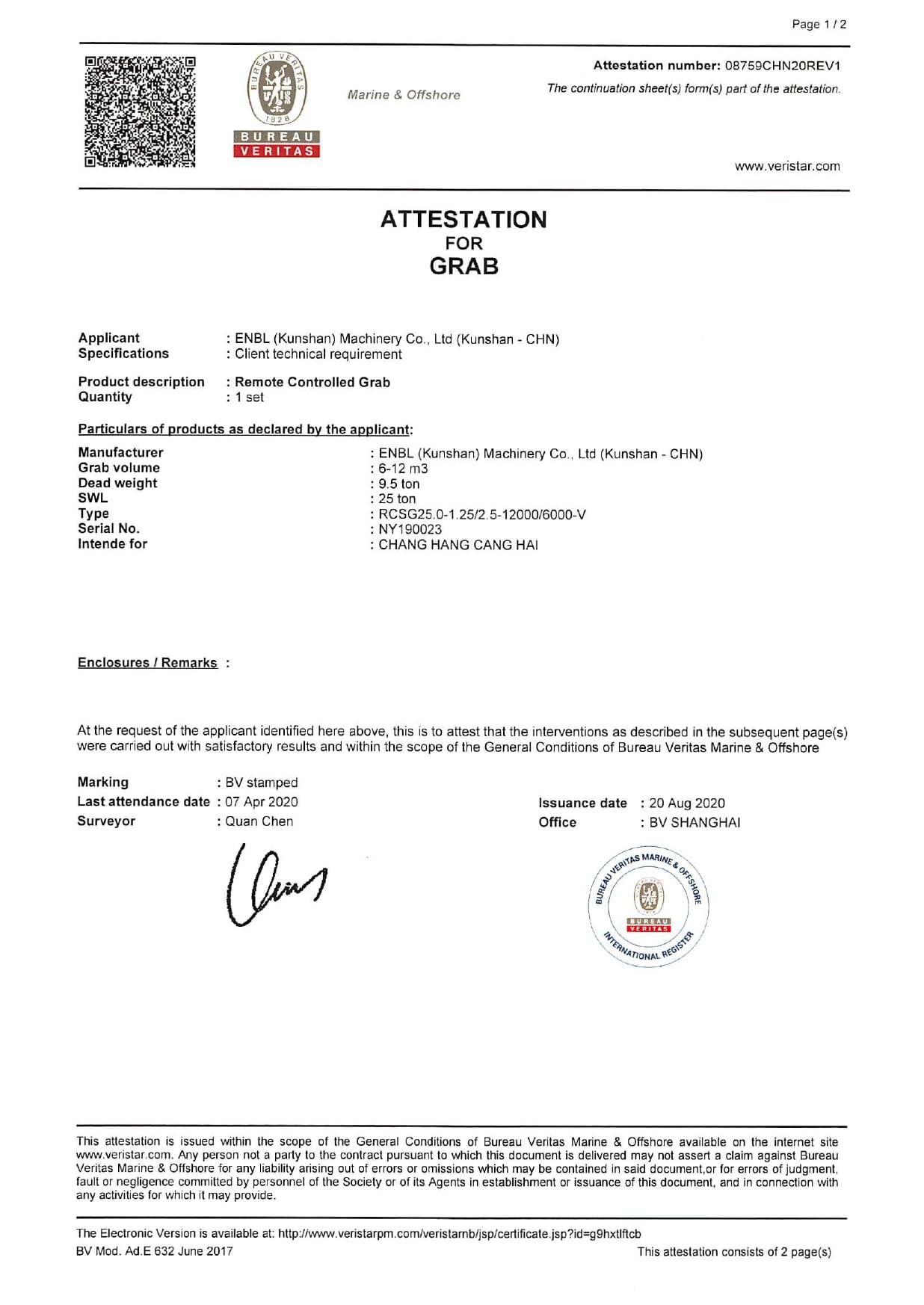

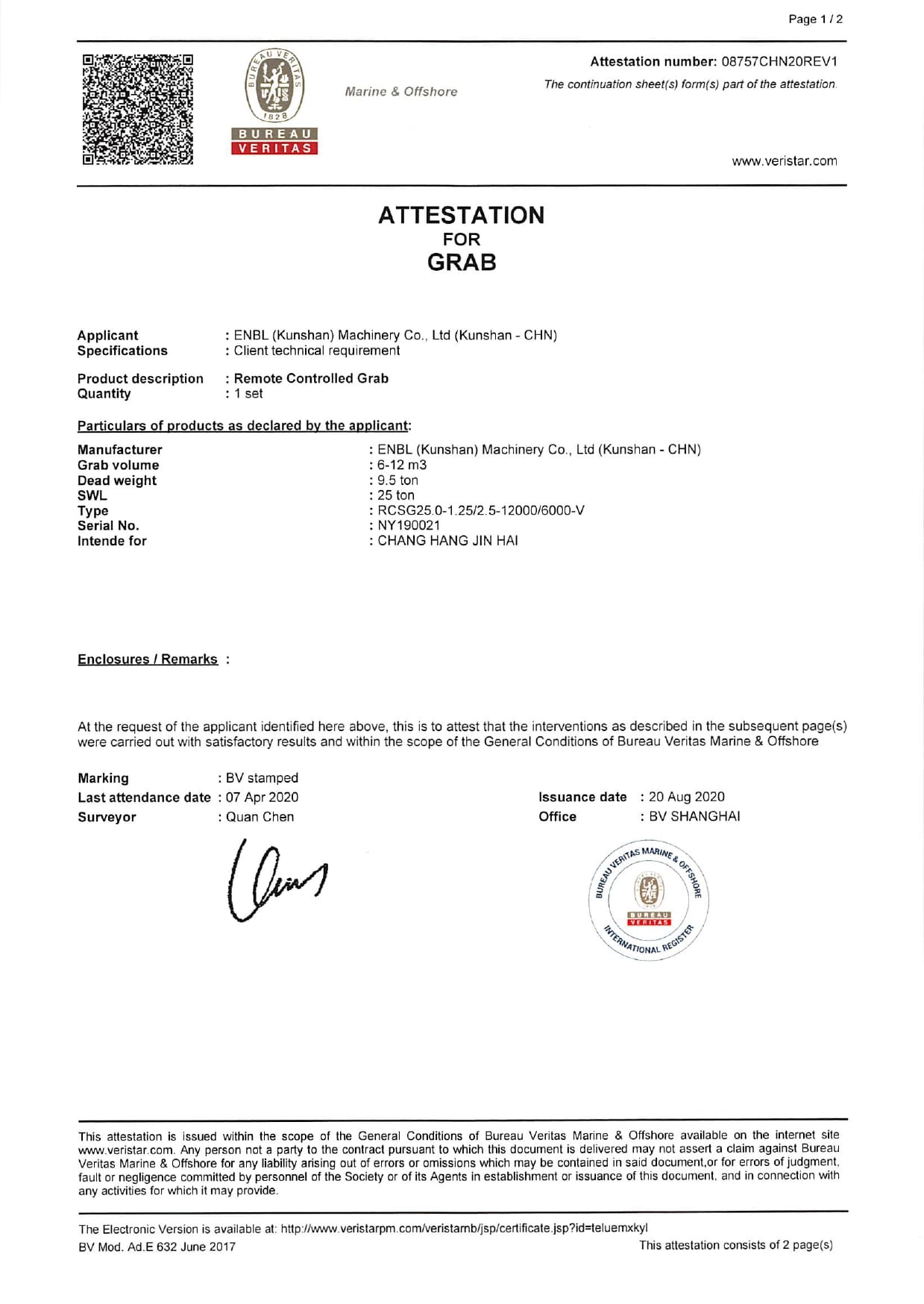

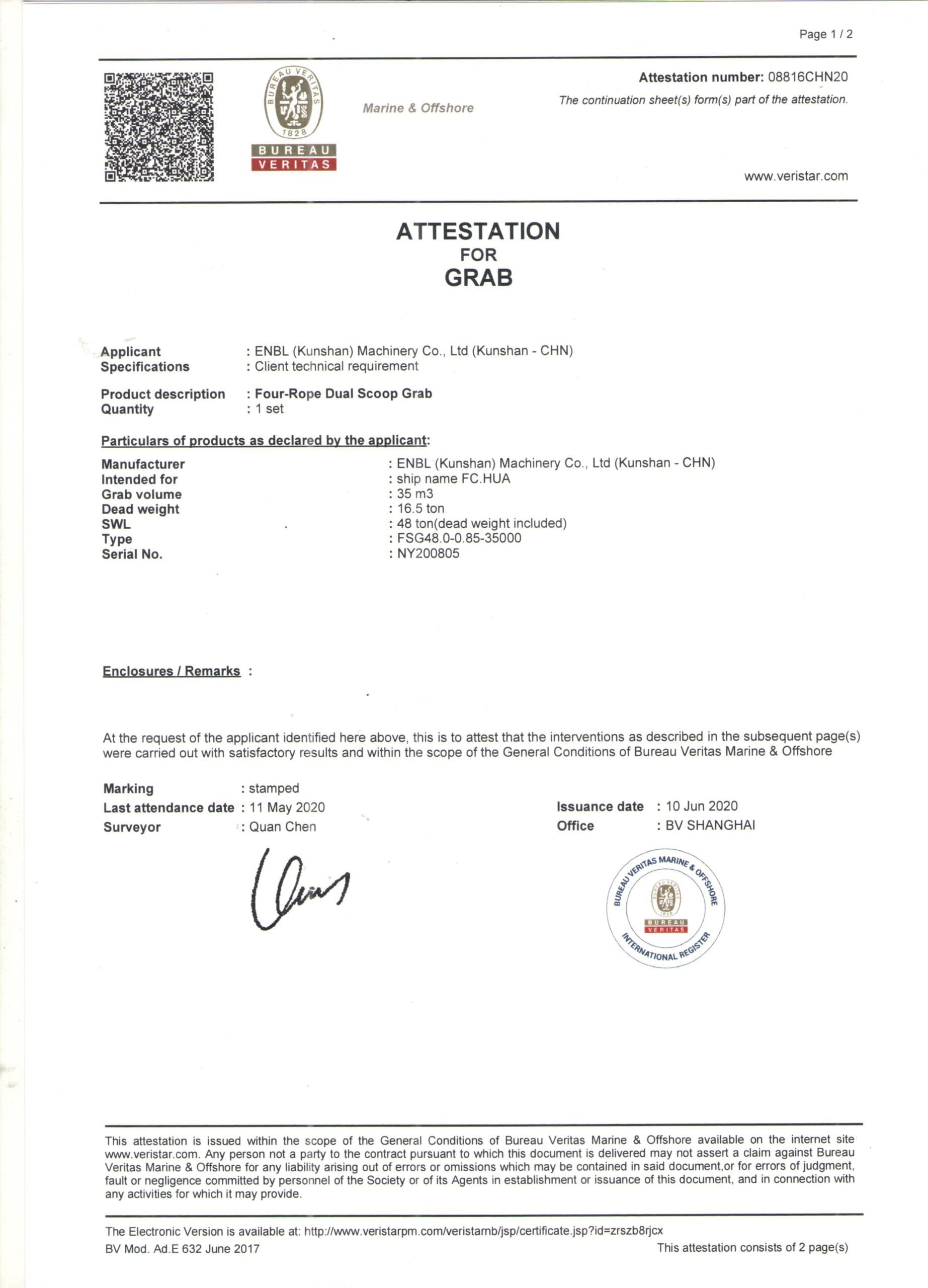

Qualification Certificate

Precision Build: The Process Behind Every ENBL Grab

Steel Plate Pretreatment

Shot blasting rusty plates to achieve Sa2.5 surface quality.

Blanking

Programming layout of parts, Using CNC plasma/CNC flame cutting machine to cut the steel plate

Milling and cleaning

Grinding and cleaning of cut parts for further processing.

Bending & Forming

Using 4500mm rolling machine to Rolling or bending parts as per drawings for accurate shaping.

Assembly & Welding

Assembling and welding key components based on the design.

Robotic Welding of Standard Parts

The traverse and scoop will be welded by robot . Also the surface welding of the scoop's wear resistance layer.

Machining

Boring and precision cutting of key grab components.

Re-shot blasting & Initial coating

Re-shot blasting & Initial coating for the main structure of the grab bucket.

Painting & Drying

Painting in spray booths followed by temperature-controlled drying.

Frozen Assembly for Precision Parts

Frozen assembly for interference-fit parts (up to -120°C) ensures precision without damage.

Final Assembly & Testing

Complete assembly, commissioning, inspection, and customer acceptance.

Delivery & Shipment

Final packaging and delivery of finished grabs to clients.

Partners